Coating Inspections

Corrosion is an unstoppable process that involve materials like metals, wood, plastics even concrete transforming engineered materials into their natural states, like steel is transformed in iron and its components, or concrete is disaggregated into initial components.

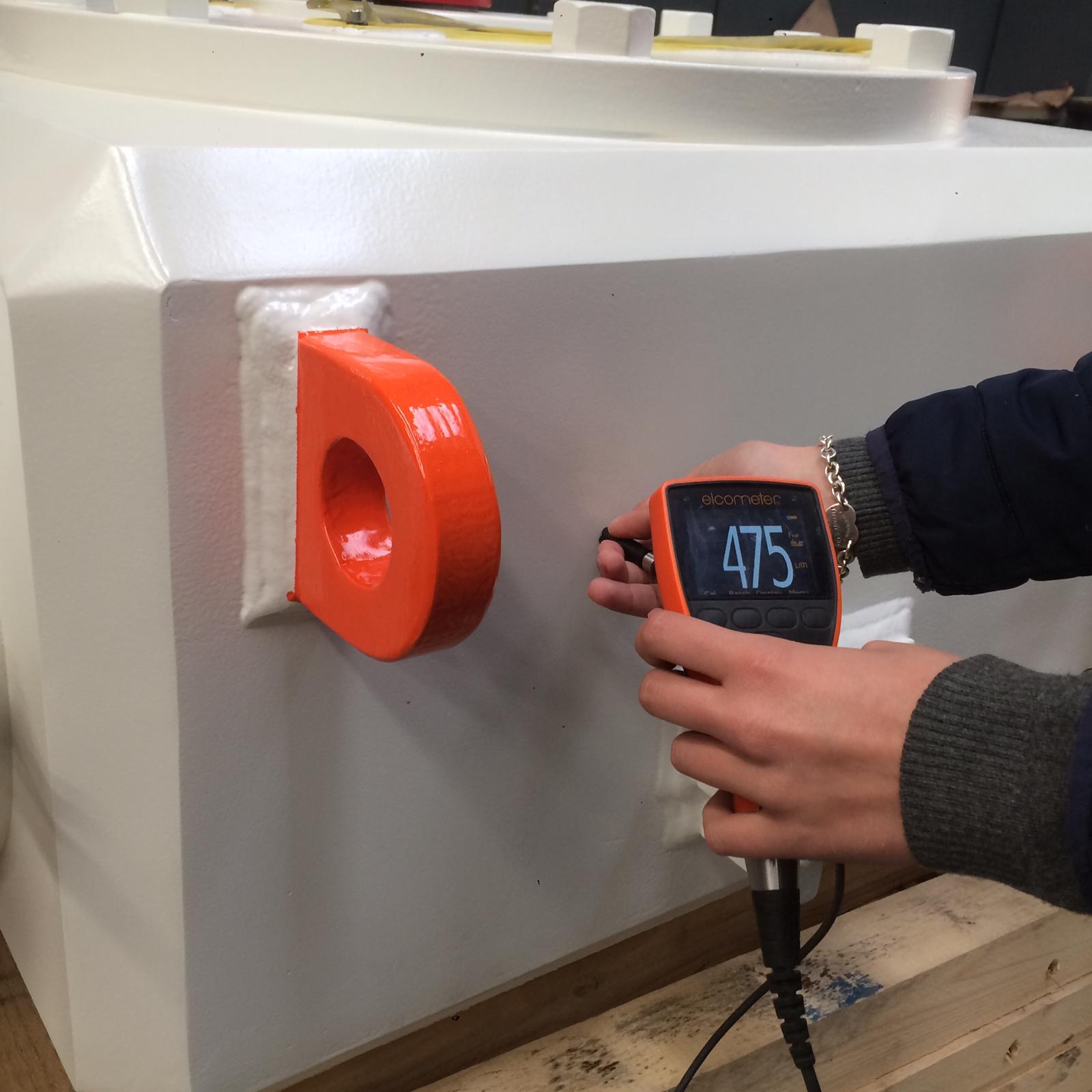

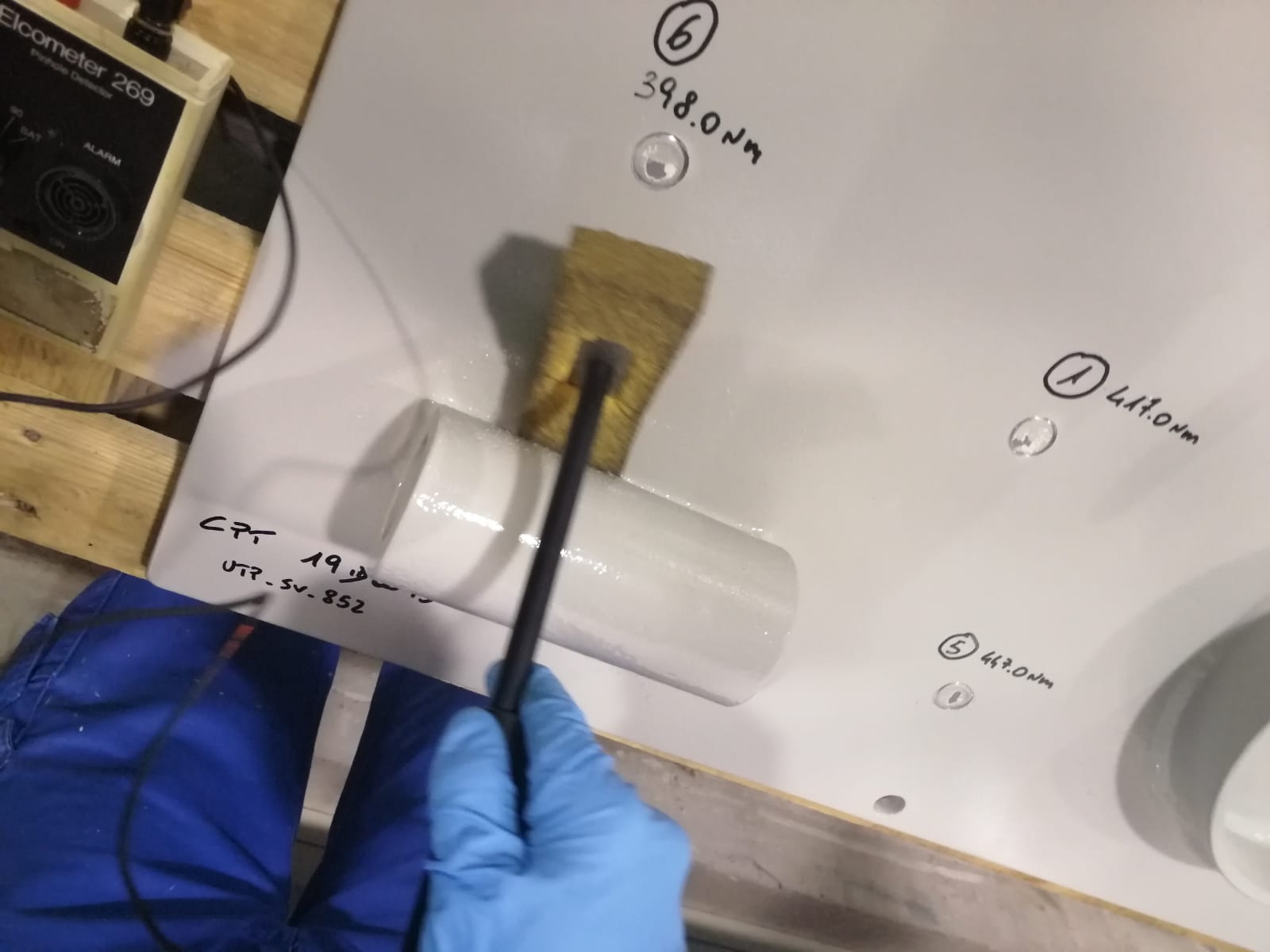

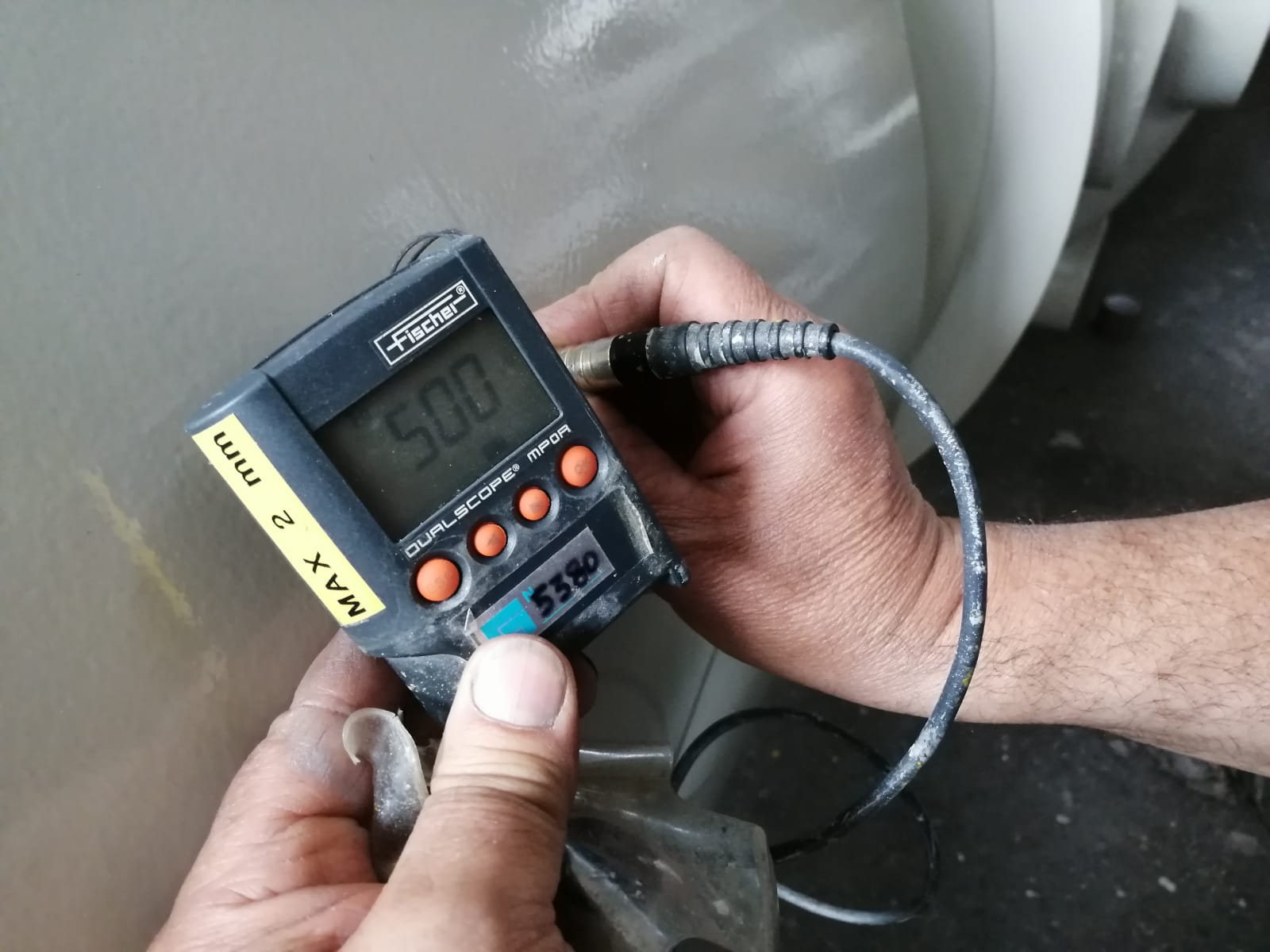

Coating is a technique used to prevent corrosion involving chemical compounds that creates a barrier in order to stop or slow the deterioration process. Is very important that the entire coating process is carried following the strict parameters and rules, since corrosion affects the life cycle and fitness for purposes of an equipment, tool or even structure, like bridges or high voltage pylons.

It has been estimated that 75% of premature coating failure is due to poor surface preparation.

With our extensive experience, we can perform inspection during initial coating, taking care of all the aspects involved in the process, or even perform a condition monitoring of the coating of an existing equipment, vessel or a structure and then take decisions for re-coating.

|

Our experience covers:

|

With our tools we can do

|

All is done with impartiality and with no compromises using our tools and, for to increase your safety we are covered with our liability insurance.

Coating

Services

Contact Us

HTC Srls

27050 Casei Gerola PV

Italy

VAT ID IT02781270182

Ph. (+39) 366.1111.853